|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rotating Wheels

By far, the most common form of skate maintenance will be rotating your

wheels. Typical skating motion can be described as pushing off your left

skate followed by pushing off you right skate and the cycle repeats. As

time goes on the inside portion of your wheels get worn. That is, the

right side of your left skate wheels and the left side of your right skate

wheels become more and more slanted. And since you tend to lean forward

as you skate the wear is worse in the front wheels. After a while a typical

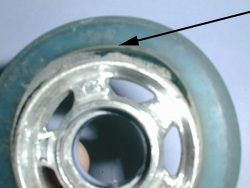

wheel on the left skate will look like this. As you can see that

|

|

|

|

|

|

beautiful parabolic shape is gone...never to

return again. I said it before and I'll say it again, if I ever win the

lottery I will have someone put spanking brand new wheels on my skates every

day. Okay, every week. The only thing to do is rotate the wheels so that

the slanted side is on the outside part of the skates. Then the whole process

starts again. Eventually your wheels acquire an inverted "V" shape.

The way I perform the rotation is as follows. I take off all my wheels (from

both skates) and line them up in a long row. I then put them is size place

order. Then divide the wheels into two stacks placing the biggest in one

stack followed by the next biggest in the other |

|

|

|

|

stack, etc. One stack will go on your left

skate the other on the right skate. You want to put the wheels back on your

skates so that, for a given stack, the largest diameter wheel goes in the

front position, followed by the second largest diameter wheel followed by

the smallest wheel in the third position and finally place the second

to smallest wheel in the back of the skate. Make sure when you are putting

the wheels back on the skates that the slanted/worn part of the wheel is

facing the outside. If your wheels are very worn prior to rotating them

your skates will feel weird when you start to skate again. But trust me

the sharp edges wear very fast and your skates will feel normal again in

a very short time. |

|

|

|

|

Bearing Maintenance

Maintaining your bearings is very important and I won't lie it's a dirty

job. Bearings have gotten cheap enough and they last long enough that

a lot of people simply buy new ones once they feel the time has arrived.

But if your an environmentalist, and like me, you feel that the bearings

have life left in them why not clean them? My honey, June would also say

that I'm CHEAP. And sometimes just one bearing locks up and then buying

a whole set is a waste of money. So this is how it's done. This will take

1-2 hours to do.

A word of warning here. WD-40 is every mechanics favorite friend but

WD-40 is actually a degreaser. That is, it removes grease and grit. So

after you spray it on something like a bearing it may appear to run smoothly

again but in fact you are removing the grease. We don't want to do that.

We want to clean our bearings and then regrease them.

Removing Your Bearings

I thought that removing the bearings was pretty simple but my cousin

Shelly called me one night not knowing how to do it so I decided to include

this on the web site. After you remove all your wheels you will need to

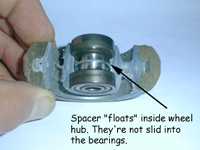

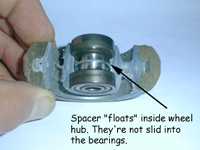

remove the bearings from them. Some skates have "floating" spacers

between the bearings while others have "captive" spacers. The

differences are unimportant although removing the bearings from the wheels

is slightly different. If the bolt that goes through your skate wheels

is 1/4" in diameter then you have "captive spacers" if

the bolt is 5/16" in daimeter then you have "floating"

spacers

|

|

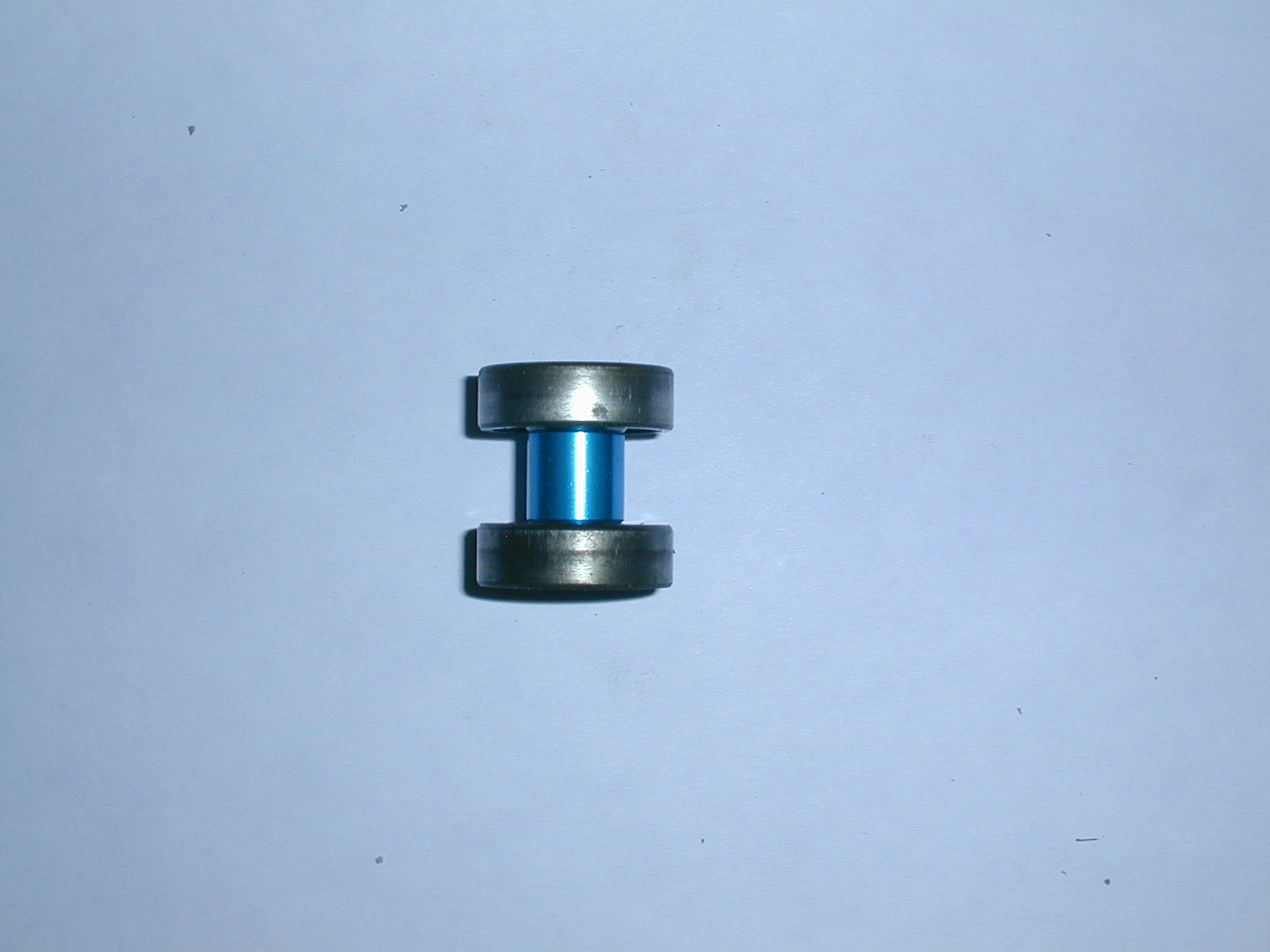

Here is a cut-away view of a wheel containing

a "captive spacer." This particular spacer is made of blue annodized

aluminum although many spacers are made of a white nylon plastic. The bearings

slide on to the spacer as shown in the two right photos |

|

|

|

|

|

|

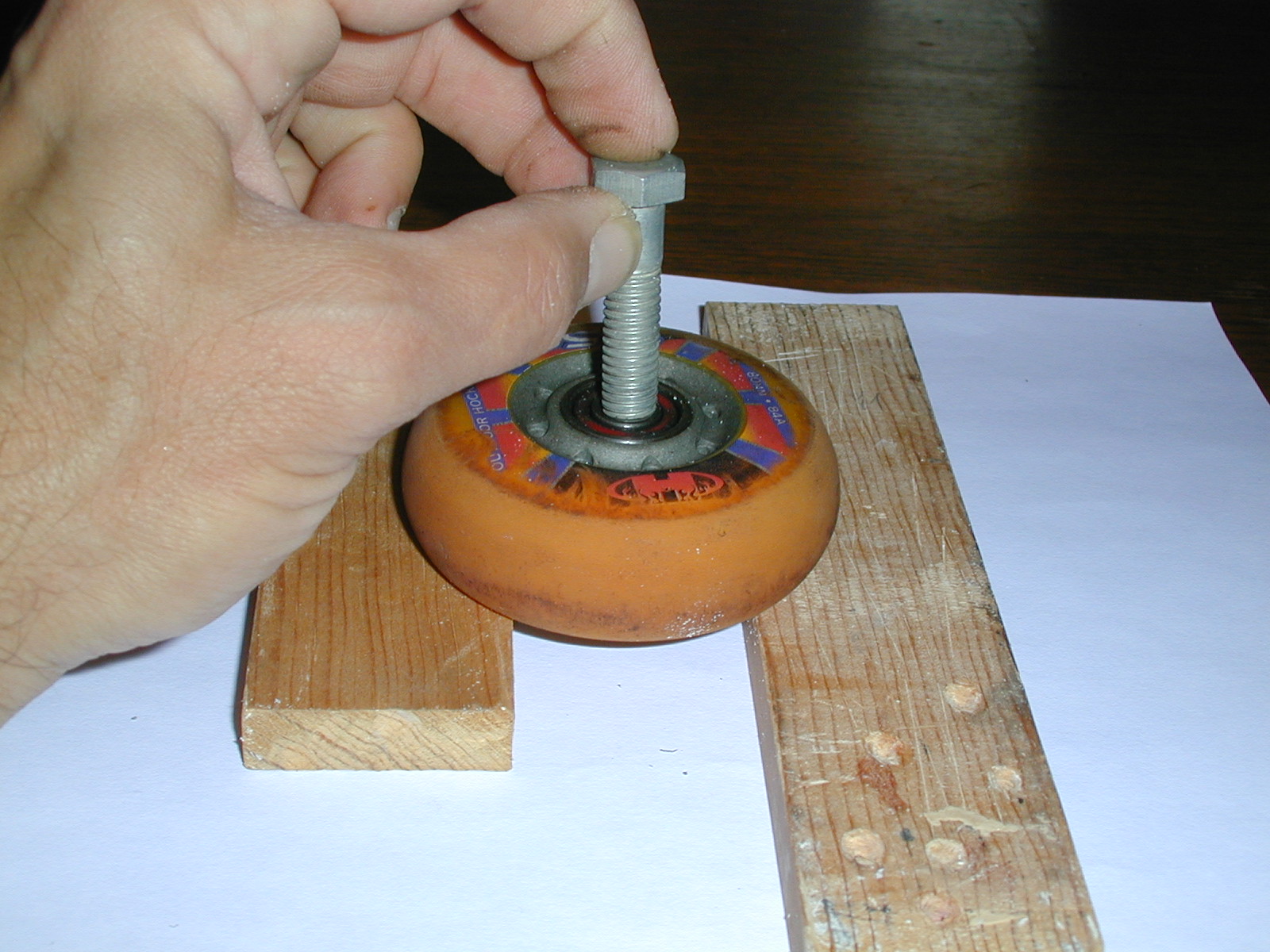

To remove these bearings there is

an inexpensive tool that makes the job easier but you can alternatively

use a 5/16" daimeter bolt or an old spacer if you have one. Simply

prop the whole wheel up on some wooden blocks and center the bolt over the

spacer. Make sure you are not on the inner race of the bearing but on the

spacer. Also make sure that there is a gap |

|

|

|

|

|

|

|

|

between the wooden blocks that will allow the bearing below to come

out. Tap gently with a small hammer until the bearing below starts to

come out. Keep tapping until the entire assembly comes out. Here you see

the lower bearing starting to come out. You will have two bearings and

one spacer for each wheel.

|

|

|

|

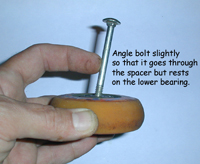

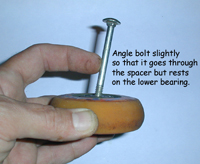

To the right is a photo of a "floating"

spacer. Since these spacer do not slide into the bearings the bolt that

goes through them is larger and is equal to the bore of the bearings, 5/16"

diameter. Further to the right you see the exploded view of the assembly.

Again, an inexpensive tool is sold to remove these bearings but alternatively

you can place a 1/4" daimeter bolt through the first bearing and on

through the |

|

|

|

|

|

|

"floating" spacer. Then angle it a

little so that it rests on the top surface of the lower bearing. Now it's

time to gently tap the bolt. I do emphasize gently. Rotate the bolt to different

sides of the lower bearing as you tap down. Do not bang hard or you will

damage the bearings. |

|

|

|

Once the lower bearing is removed you can flip

the wheel over and use the same technique on the other side. Just be gentle.

Sometimes they are a bit hard to |

|

|

|

remove and you must tap them all around the rim to get them free, not

unlike loosening a jar top. Once this is done seperate the bearing from

the spacers. Don't lose any thing. There are eight wheels, eight spacers,

and sixteen bearings. I put them in cups.

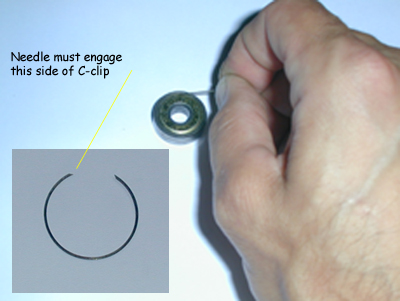

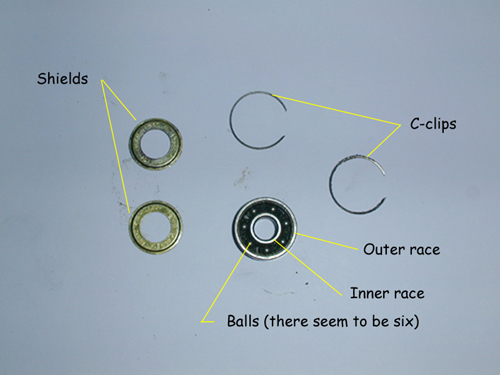

To clean the bearings properly you must remove the shields. Each bearing

has a shield on the top and back side to protect it from dust and debris.

Some companies will tell you to remove only one of the shields but trust

me it's much better to remove both of them. I told you this would take

a long time. If your bearings don't have shields they're probably crumy

bearings and not worth the trouble to clean them. To remove the shields

you must remove the "C"-clips that hold them in place. Use a

needle and slide it around the rim of the bearing until it engages the

part of the C clip that is angled (see photo)

|

|

|

Note here that one side of the C-clip is angled

so that the needle will engage with it while the other side is angled in

the other direction and the needle will slip off of it. Since you don't

know the C-clip's orientation you will have to feel for the engagement.

Once you feel the needle go in pry out the C-clip. Be careful because these

babies can go flying off and you probably won't find it. I place my hand

over the bearing to catch the flying C-clip. Once removed, the shield is

free to come off. However, removing it can still be a bit maddening.I frequently

pick up the bearing and throw it on the floor so that its edge hits |

|

|

the floor just right. This usually knocks out the shield. If not, throw

it again. Once you have removed the C-clips and shields you will expose

the bearing's cage and balls. Now the hard part is over. At this point

you will have, sixteen bearings, thirty two shields and thirty two C-clips.

Don't lose them!

|

|

|

|

Now you need to clean the bearings. The best

thing to do and the best environmentally sound thing to do is buy one of

the many citrus cleaners sold at skate stores. Soak the bearings in the

cleaner for a good while (20 minutes or so). When done you can run them

under the faucet and allow the water pressure to push away any stuck on

debris. Now use a blow dryer to dry the bearings so that they don't rust. |

|

|

|

If you don't have a blow dryer perhaps it's

better to skip the faucet cleaning step. These bearings will rust if they

get wet. Allow the bearings to dry completely. Now you are ready to apply

the grease. Let's talk a little about grease. I work in a machine shop that

has a numerically controlled milling machine that uses a high pressure grease.

It's thick and red in color and basically really top of the line stuff.

But if you can't get that there are many others out there. I like it to

be thick. That way it stays in the bearing. Some products claim to be lightening

lube but they're too thin and I think they will simply run out of the bearing.

Another good product are these teflon greases sold in bicycle shops. It

is often white in color. The |

|

|

|

key here is to not put too much grease in the

bearings. If you put too much grease in them the balls will not rotate as

the bearing spins. Rather they will slide because there is too much grease.

You want to avoid this at all costs. Put a little dollop of grease in the

bearing and try to spread it around. Rotate the bearing so it gets evenly

distributed. Now it's time to put back the shields. Get the C-clip started

by angling it into its internal groove (lower right). Then give the finger

roll until you here it click into position. I sometimes run the needle around

the ourtside of the shield |

|

|

to make sure the C-clip is seated properly. Only thirty one more C-clips

to go and you're done.

Well, you may never do this again but at least you know how to. Cleaning

your bearings is good for the soul and makes you a better person. I don't

know about making you a better skater.

|

|

|

|

Additonal Maintenance

I don't know of any other maintenance for skating other than reminding

you to ocassionally wash your wrist guards as they will eventually get

a bit funky. But remember to always examine your skates.

|

|

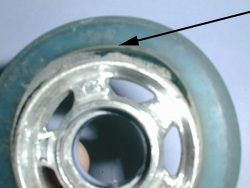

When the wheels get pretty worn, what's left

of the polyurethane wheel will become precariously close to the inner plastic

core of the wheel hub. When this happens the polyurethane wheel will break

off the core. The wheel is said to have "decored." Here you can

see the arrow pointing the area that is starting to decore. The tire is

literally pulling away from the inner core. This is dangerous because your

wheel will immediately start to rub against the frame preventing it from

freely rotating. The end result is often an immediate and sometimes painful

fall. So keep your wheels in check. If this wheel were still in use I would

estimate that in less than 5 minutes the entire tire would come off. It

happened to me once when |

|

I was skating and resulted in a wicked fall. Just remember. when skating

becomes slow and unresponsive check your wheels and your bearings. I skate

to work almost every day (around 3 miles each way). I also do a lot of

skating on the weekends. I go through a new set of wheels about every

6 weeks and I rotate my wheels almost every week. Such is the life of

an avid skater.

Remember to check for other things like missing rivets, cracks in the

wheel frames, worn laces, etc. A lot is riding on your skates so inspect

them as you would your car.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|